Scope Transportation Logistics, and the Petroleum Refining Industry Transportation logistics in the petroleum

Gosyen Haromain Integration Scope Transportation Logistics, and the Petroleum Refining Industry

Company Gosyen Haromain Integration Scope Transportation Logistics, and the Petroleum Refining Industry

Transportation logistics in the petroleum refining industry involves managing the complex flow of raw materials and finished products to and from refineries and distribution centers. This includes:

1. Supply Chain Management: Coordinating the transportation of crude oil from extraction sites to refineries and then distributing refined products like gasoline, diesel, and jet fuel to end consumers or storage facilities.

2. Logistics Planning: Optimizing transportation routes and modes (pipeline, rail, tanker truck) to ensure timely delivery while minimizing costs and environmental impact.

3. Inventory Management: Maintaining adequate inventory levels of both crude oil and refined products to meet demand fluctuations without overstocking, which requires efficient storage and distribution facilities.

4. Regulatory Compliance: Ensuring compliance with transportation regulations, safety standards, and environmental laws related to the handling and transportation of petroleum products.

5. Technology Integration: Implementing advanced technologies such as GPS tracking, IoT sensors, and data analytics to monitor shipments in real-time, improve efficiency, and enhance safety.

6. Risk Management: Mitigating risks associated with transportation, such as supply chain disruptions, geopolitical issues affecting oil supply routes, and safety hazards during transportation.

Overall, effective transportation logistics in the petroleum refining industry is crucial for ensuring smooth operations, minimizing costs, and meeting the demands of global energy markets.

TIME CHARTER PROCESS SERVICES

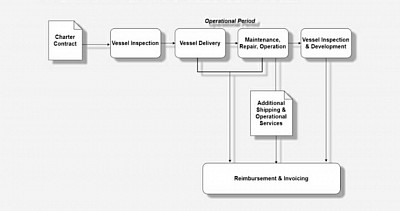

In conducting a vessel chartering transaction, after obtaining an explanation or request for a contract from the charterer, the Company will first check the availability of the vessel and perform physical inspection to ensure operational feasibility and the compliance with charterer requirements. After the vessel meets the requirements, the Company will deliver the vessel to the charterer in their operational area.

Sometimes, during the operational period, there are several purchases of charterer supplies or needs (such as pipe installation, water or food supply) which are not covered by the charter contract. In such situation, the Company will provide additional services with additional service costs borne in advance by the Company to be reimbursed by the charterer.

In providing its services, the Company can obtain payments or reimbursements that can be invoiced during the operational period and/or after inspection and redelivery of the vessel has been carried out. This depends on the terms of payment agreed in the charter service agreement or service contract.

Sʜɪᴘs ᴍᴀɴᴀɢᴇᴍᴇɴᴛ sʏsᴛᴇᴍs

"We are proud of who we are and what we do."

Gosyen Haromain Integration Group company to serve the marine and offshore industry by providing qualified and reliable marine personnel.

the company expanded its capabilities to include full Ship Management services by establishing Gosyen haromain integration Shipmanagement and agency

Gosyen haromain integration Shipmanagement is a boutique third party ship manager who specializes in managing dry bulk vessels, Oil Tankers. The company is committed to providing cost-effective ship management services without compromising safety and quality.

Management is steadfast in their approach to ORGANIC AND SUSTAINABLE growth which is evident in the slow but steady growth rate of vessels under our management.

We understand that every owner and ship is unique, that's why WE DO NOT believe in the typical “One Size fits All” approach.

Personalized touch in our services is our unique value proposition.

Products and Services

The Company is a shipping company that specializes in providing offshore vessels to support the business activities of the upstream oil and gas industries.

The Company rents out its own vessels based on time charter in return for rental based on tenders or negotiations between the two parties. During the rental period, the lessee is responsible for paying all travel expenses, including costs of fuel and port. On the other hand, as a vessel owner, the Company is responsible for vessel crews, vessel maintenance, spare parts, and other operational costs, all of which have been calculated in the rental fees agreed by both parties. In this time charter scheme, the charterers rent the vessel and crews in full for a certain period.

business activities

The scope of business activities of the Company is to engage in the field of shipping, which includes:

To engage a chartering business by using various types of vessels, including to support the activities of oil and gas and other mining companies, including tug boats, crew boats, AHT and AHTS, SPOB, floating storage offloading (FSO), floating production storage and offloading (FPSO), accommodation and work barge.To engage maritime transportation business activities for goods and passengers between ports in Indonesia which are carried out in stages and regular basis and/or non-permanent and irregular shipping;To engage business as owner’s representative of sea freight shipping companies, both permanent and non-permanent shipping for domestic and overseas shippingTo engage a business of freight transportation of oil/gas using tankers.

EN590-10 PPM

EN590 Diesel Fuel standard for outlines specific technical requirements and characteristics to ensure the quality and compatibility of diesel fuels used in road vehicles.

Composition and Properties:

Sulfur Content: EN590 sets limits on sulfur content, aiming to reduce emissions and air pollution. Ultra-low sulfur diesel (ULSD) with sulfur content typically not exceeding 10 parts per million (ppm) is a common requirement.

Density and Viscosity:

Specifies acceptable density and viscosity ranges to ensure proper combustion and engine performance.

Cetane Number:

Defines the minimum cetane number, which indicates the ignition quality of the diesel fuel. Higher cetane numbers generally result in better combustion.

Distillation Characteristics:

Specifies distillation temperature ranges to ensure that the fuel evaporates and ignites within optimal engine conditions.

Cold Flow Properties:

Addresses cold weather performance, including cloud point and cold filter plugging point, to prevent fuel gelling in low temperatures.

Compliance Standards:

EN590 aligns standards, supporting the use of advanced emission control technologies in diesel engines to reduce pollutants.

Biodiesel Blending:

The standard allows for the blending of diesel with biodiesel, up to certain specified percentages, promoting the use of renewable fuels and addressing environmental concerns.

Quality Assurance:

EN590 ensures consistent fuel quality by establishing testing methods and quality control measures. Compliance with these standards helps maintain the efficiency and reliability of diesel engines.

Regulatory Compliance:

Diesel fuels meeting EN590 standards are widely accepted in European countries and are often required for use in modern diesel engines.

Future Developments:

Standards may evolve to address emerging technologies, environmental concerns, and changes in the automotive industry, ensuring that diesel fuels remain compatible with modern engines.

Standards may evolve to address emerging technologies, environmental concerns, and changes in the automotive industry, ensuring that diesel fuels remain compatible with modern engines.

Crude Oil

Crude Oil: Unveiling the Essence of a Global Energy Icon Welcome to a comprehensive exploration of one of the world’s most pivotal resources—Crude Oil. This foundational substance serves as the lifeblood of our modern energy landscape, driving industries, economies, and innovations worldwide. Let’s delve into the multifaceted aspects that define Crude Oil.

Understanding Crude OilOrigins and Formation :

Unearth the geological origins of Crude Oil, tracing its formation from ancient marine organisms to the vast reservoirs beneath the Earth’s surface. Explore the science behind its composition and the factors influencing its diverse characteristics.

Exploration and Extraction :

Embark on the journey of exploration and extraction, where cutting-edge technologies and expertise converge to locate and extract crude oil reservoirs. Understand the significance of oil wells, drilling techniques, and the challenges inherent in these operations.

The Composition of Crude OilHydrocarbon Mix :

Uncover the intricate mix of hydrocarbons that make up Crude Oil, ranging from simple molecules like methane to complex compounds like asphalt. Learn how this varied composition dictates the range of products derived from crude oil.

Fractions and Distillation :

Explore the refining process, where crude oil undergoes fractional distillation to separate it into distinct fractions based on boiling points. Witness the birth of essential products like gasoline, diesel, jet fuel, and various petrochemicals.

Global Significance Economic Impact :

Understand the profound economic impact of Crude Oil on global markets. Delve into its role as a commodity, influencing prices, trade relationships, and geopolitical dynamics.

Energy Source:

Grasp the fundamental role Crude Oil plays as a primary source of energy. Explore its use in transportation, electricity generation, and various industrial applications that power the engines of modern society.

Environmental ConsiderationsEnvironmental Impact :

Confront the environmental challenges associated with Crude Oil extraction, transportation, and consumption. Learn about spill response measures, environmental regulations, and ongoing efforts to mitigate the ecological footprint of the oil industry.

Alternatives and Sustainability :

Explore the evolving landscape of renewable energy alternatives and sustainable practices that aim to reduce dependency on crude oil and address environmental concerns.

Future PerspectivesTechnological Advancements :

Stay abreast of the latest technological innovations in the oil industry, from enhanced extraction techniques to advancements in refining processes. Witness how technology is shaping the future of crude oil utilization.

Global Energy Transition :

Examine the ongoing global shift towards cleaner and more sustainable energy sources. Discover how the energy landscape is evolving and the role that crude oil plays in this transformative journey

Light Cycle Oil (LCO)

Light Cycle Oil (LCO) : Unveiling the Versatile Byproduct of Refining Light Cycle Oil (LCO) emerges as a valuable by product in the intricate dance of molecules within the petroleum refinery, specifically during the fluid catalytic cracking (FCC) process. This refined petroleum product occupies a strategic position in the hierarchy of hydrocarbons, offering a bridge between the heavier and lighter fractions of the refined spectrum

Origins in FCC Process :

LCO’s genesis can be traced back to the FCC process, where the alchemy of catalysis transforms heavy hydrocarbons into a symphony of lighter and more lucrative products. As the catalyst facilitates the cracking of complex hydrocarbons, LCO emerges as a mid-distillate, embodying characteristics between the realms of gasoline and diesel.

Composition and Characteristics :

Comprising a diverse mix of hydrocarbons with varying molecular weights, LCO is bestowed with a unique set of properties. It possesses a higher boiling point than gasoline but remains lighter than traditional diesel fuel. This composition renders LCO a versatile substance with applications spanning multiple facets of the petrochemical industry.

Applications in Various Arenas :

LCO’s adaptability finds expression in diverse applications within the industry. Whether destined for further processing or becoming a blending feedstock, LCO seamlessly integrates into the refinery’s operational tapestry, responding to the demands of the market.

Blending Feedstock :

A notable role for LCO lies as a blending feedstock, contributing its distinct properties to the creation of refined products. Refineries wield the power to adjust blending ratios, ensuring that the final products meet the stringent specifications required by the market.

Market Dynamics and Economic Significance :

The market dynamics surrounding LCO are a reflection of refinery configurations, product demand fluctuations, and the ever-evolving landscape of regulatory standards. Refineries strategically optimize their processes to maximize LCO yields, recognizing its economic significance as a valuable commodity derived from the refining alchemy.

Regulatory Compliance :

Like all refined products, LCO is subject to regulatory scrutiny to ensure adherence to quality standards and environmental regulations. Refineries must meet these standards, ensuring that LCO not only meets market demands but also aligns with environmental and safety considerations.

In the grand tapestry of the petroleum refining process, Light Cycle Oil (LCO) emerges as a versatile player, navigating the delicate balance between heavy and light hydrocarbons. Its journey from the FCC unit to various applications showcases the industry’s adaptability and commitment to maximizing the value derived from every drop of crude oil. As the energy landscape continues to evolve, LCO remains a dynamic component, playing a vital role in meeting the world’s ever-growing demand for refined petroleum products

Liquified Natural Gas (LNG)

Liquified Natural Gas (LNG) LNG stands for Liquefied Natural Gas. It is natural gas that has been cooled to a point where it condenses into a liquid form for ease of storage and transportation. The liquefaction process involves reducing the temperature of natural gas to around -260°F (-162°C), at which point it becomes a clear, colorless, and non-toxic liquid.

Composition :

LNG is primarily composed of methane, with small amounts of other hydrocarbons. It is sourced from natural gas fields and can also be produced as a byproduct of oil extraction.

Liquefaction Process :

The process of liquefying natural gas involves removing impurities and cooling the gas to extremely low temperatures. This makes LNG more compact and enables it to be transported over long distances in specialized cryogenic tanker ships.

Transportation :

LNG is transported in specially designed double-hulled ships equipped with cryogenic insulation. These ships are capable of maintaining the extremely low temperatures required to keep the gas in its liquid state.

Storage :

Once LNG reaches its destination, it is stored in large cryogenic tanks until it is needed. These tanks are designed to keep the LNG in a liquid state until it is regasified for distribution.

Regasification :

Before it can be used, LNG must be converted back into a gaseous state through a process called regasification. This can be done at receiving terminals, and the gas is then distributed through pipelines for various uses.

Uses :

LNG has diverse applications, including power generation, industrial processes, heating, and as a fuel for vehicles. It is considered a cleaner-burning fuel compared to some other fossil fuels, as it produces fewer emissions when burned.

Global Trade :

LNG is a key player in the global energy market, with significant trade occurring between countries. Exporters, such as Qatar, Australia, and the United States, play a crucial role in supplying LNG to importing nations.

Environmental Considerations :

While LNG is often considered a cleaner alternative to some traditional fossil fuels, there are still environmental concerns associated with its extraction, production, and transportation. Methane, the primary component of natural gas, is a potent greenhouse gas, and its release into the atmosphere can contribute to climate change.

Infrastructure Development :

The utilization of LNG requires significant infrastructure, including liquefaction plants, regasification terminals, and transportation networks. Countries interested in incorporating LNG into their energy mix often invest in such infrastructure.

Liquified Petroleum Gas (LPG)

Liquified Petroleum Gas (LPG) Unleashing the Power of Clean and Versatile Energy, Introduction to LPG: Liquefied Petroleum Gas, commonly known as LPG, emerges as a dynamic and flexible energy source derived from the refining of crude oil and natural gas. Comprising primarily propane and butane, LPG stands out for its ability to seamlessly transition between gaseous and liquid states, unlocking a realm of possibilities for a diverse range of applications.

Physical Transformation for Practicality :

What sets LPG apart is its unique ability to exist as a gas under normal atmospheric conditions but transform into a liquid under moderate pressure or cooling. This physical adaptability makes LPG highly portable, facilitating convenient storage and transportation.

Applications Across Diverse Sectors:

LPG’s versatility spans across residential, commercial, and industrial sectors, making it a preferred choice for a myriad of applications. From cooking and heating in homes to serving as a dependable fuel source for vehicles, industries, and agriculture, LPG is the go-to solution for diverse energy needs.

Clean-Burning Characteristics :

A standout advantage of LPG is its status as a clean-burning fuel. Combusting with minimal emissions, LPG significantly reduces the release of pollutants compared to traditional solid fuels, positioning it as an environmentally friendly and sustainable energy option.

Residential Convenience :

In households, LPG is a cornerstone for cooking and heating. Its quick ignition, consistent flame, and efficient energy output make it an indispensable energy source, offering households a reliable and accessible solution.

Commercial & Industrial Prowess :

LPG’s adaptability extends into the commercial and industrial realms, where it fuels space heating, water heating, and various processes. Its versatility in meeting diverse energy demands underscores its significance in these sectors.

Automotive Innovation :

As an alternative automotive fuel, LPG provides a cleaner-burning option for vehicles. Cost-effective and environmentally conscious, it has gained popularity in regions seeking sustainable transportation solutions.

Environmental Stewardship :

LPG champions environmental responsibility by emitting fewer greenhouse gases and air pollutants compared to traditional fossil fuels. Its use contributes to mitigating air pollution and reducing the overall environmental footprint associated with energy consumption.

Efficient Storage and Distribution :

LPG is efficiently stored and distributed in specialized containers, ensuring safety and ease of use. Its portability allows for widespread accessibility, even in areas without direct access to natural gas pipelines.

Safety at the Forefront :

Stringent safety measures govern the handling and utilization of LPG. Equipped with safety valves, odorants for leak detection, and strict adherence to regulatory standards, LPG ensures a secure and reliable energy source across diverse applications.

Stringent safety measures govern the handling and utilization of LPG. Equipped with safety valves, odorants for leak detection, and strict adherence to regulatory standards, LPG ensures a secure and reliable energy source across diverse applications.

Gasoline

Gasoline, often referred to as petrol, is a liquid fuel derived from crude oil through a refining process. Here are the key components and characteristics of gasoline:

Hydrocarbons :

Gasoline is primarily composed of hydrocarbons, which are organic compounds consisting of hydrogen and carbon atoms. The hydrocarbons in gasoline are typically in the range of C5 to C12, meaning they have 5 to 12 carbon atoms per molecule.

Octane Rating :

Gasoline’s performance is often measured by its octane rating, which indicates its resistance to knocking or pinging during combustion in an engine. Higher-octane gasoline is less prone to premature ignition and is commonly used in high-performance or high-compression engines.

Additives :

Gasoline may contain various additives to enhance its properties and performance. Common additives include detergents to clean fuel injectors and intake valves, corrosion inhibitors, antioxidants, and anti-knock agents.

Distillation Fractions :

During the refining process, crude oil is distilled to separate it into different fractions based on boiling points. Gasoline is derived from the lighter fractions of crude oil, typically in the range of 30 to 200 degrees Celsius (86 to 392 degrees Fahrenheit).

Aromatics and Olefins:

Gasoline may contain aromatic hydrocarbons (such as benzene, toluene, and xylene) and olefins (unsaturated hydrocarbons) in varying proportions. The composition of these components can affect the combustion characteristics of the fuel.

Vapor Pressure :

Gasoline is designed to have a specific vapor pressure, which influences its ability to evaporate at various temperatures. Controlling vapor pressure is important for proper engine performance and emissions control.

Environmental Stewardship :

LPG champions environmental responsibility by emitting fewer greenhouse gases and air pollutants compared to traditional fossil fuels. Its use contributes to mitigating air pollution and reducing the overall environmental footprint associated with energy consumption.

Ethanol Blending:

In some regions, gasoline is blended with ethanol, a biofuel usually derived from corn or sugarcane. Gasoline with ethanol blends, such as E10 (10% ethanol) or E85 (up to 85% ethanol), is common in certain markets as a means of reducing dependence on fossil fuels and lowering emissions.

Color and Odor :

Gasoline is typically colorless and has a characteristic odor. The odor is often due to the presence of volatile compounds like benzene. The distinct smell is also an important safety feature, allowing people to detect gasoline leaks.

Environmental Impact :

The combustion of gasoline in internal combustion engines produces carbon dioxide (CO2) and other pollutants. Efforts to reduce the environmental impact of gasoline focus on improving fuel efficiency, developing cleaner combustion technologies, and promoting alternative fuels.

It’s important to note that gasoline formulations may vary by region and are subject to regulatory standards. Additionally, advancements in fuel technology and changes in regulations may impact the composition of gasoline over time.

Jet A-1 Aviation Fuel

Jet A-1 Aviation Fuel Definition Jet A-1 is a type of aviation fuel primarily used in commercial and civilian jet aircraft. It is a kerosene-based fuel specifically designed for use in aviation turbine engines

Composition :

Hydrocarbons: Jet A-1 is composed of hydrocarbons, similar to other kerosene-based fuels.

Additives :

It may contain additives to enhance its properties, including anti-static agents, corrosion inhibitors, and fuel system icing inhibitors.

Properties :

Flash Point: Jet A-1 has a relatively high flash point, reducing the risk of fire during handling and storage.

Freezing Point :

The fuel is designed to have a low freezing point to prevent gelling at high altitudes and low temperatures.

Density :

Jet A-1 has a specific density that allows for efficient storage and transportation.

Specifications :

Jet A-1 conforms to specific international specifications, including those set by organizations such as the International Air Transport Association (IATA) and the American Society for Testing and Materials (ASTM).

Use in Jet Engines :

Jet A-1 is suitable for use in various types of jet engines, including turbofan and turboprop engines, which are commonly found in commercial airliners.

Availability :

Jet A-1 is widely available at airports around the world, ensuring a consistent fuel supply for the aviation industry.

Regulatory Compliance:

Jet A-1 must meet stringent aviation fuel standards and regulations to ensure safety and optimal engine performance.

Safety Considerations:

The use and handling of Jet A-1 involve strict safety protocols, and it is crucial for aviation professionals to adhere to established guidelines.

Environmental Impact :

Efforts are ongoing to develop alternative aviation fuels with lower carbon emissions, but Jet A-1 remains the predominant fuel for aviation at present.

Understanding the properties and specifications of Jet A-1 is essential for pilots, aviation fuel providers, and regulatory bodies to ensure the safety and efficiency of air travel.